Recycling plastic into panels for Peter Pearce’s Curved Space structure presents several challenges, from understanding material properties to refining the molding process. Through this series of experiments, we explored different plastic types, tested different melting techniques to create saddle pentagon panels.

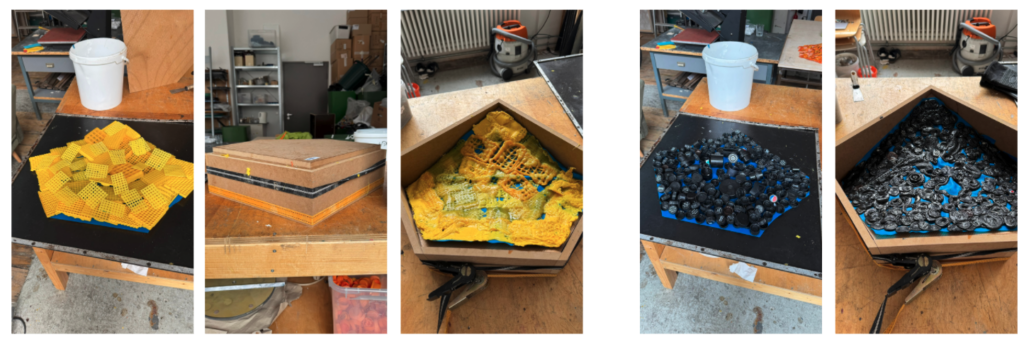

Mold Preparation

To create the saddle pentagon panels, we built a custom mold using MDF sheets, consisting of a bottom part and a negative top part to press the plastic in between. To prevent the molten plastic from sticking to the mold, we applied a wood glue coating. Once the mold was ready, we brought it to the Precious Plastic workspace at WUK Vienna, where we produced our experiments (special thanks to Precious Plastic Vienna).

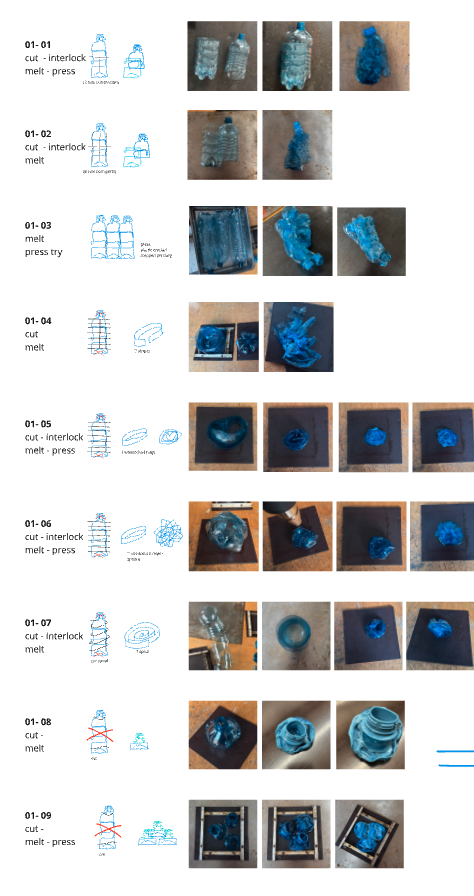

Testing Different Plastics: Small-Scale Experiments

Before shaping the plastic into the saddle pentagon mold, we conducted 10×10 cm sample tests to understand how different plastics behave during melting and cooling.

Plastic Types & Key Findings:

PET Bottles

- Shrink significantly before fully melting.

- Melt unevenly, making it difficult to bond pieces together.

- Overheating causes crystallization, turning the material white.

- Hardens quickly, allowing little time for shaping.

- Once solidified, PET becomes rigid and prone to cracking.

HDPE Bottle Caps

- Shows slight shrinkage but remains moldable longer.

- Retains a viscous state, allowing for easier shaping.

- Bonds effectively in its molten state.

- More flexible and less brittle than PET.

PP Microtube Racks

- Similar in behavior to HDPE.

- Offers good flexibility and moldability.

From these tests, we concluded that PET was unsuitable for our molding process, while HDPE and PP showed promising results.

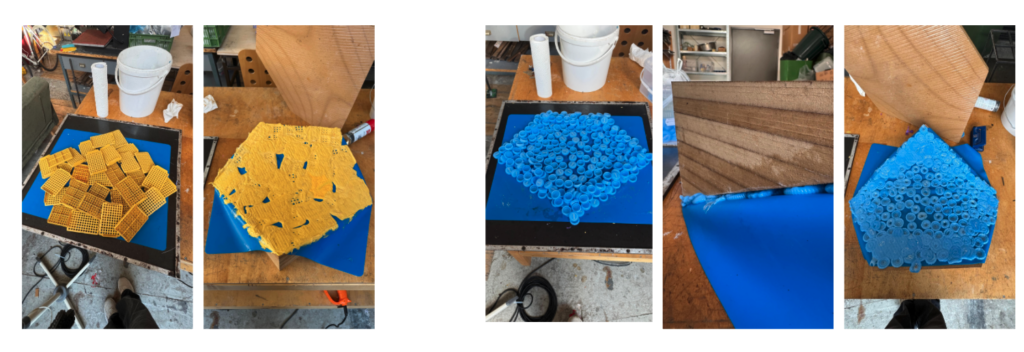

Scaling Up: Molding Saddle Pentagon Panels

With a better understanding of the material properties, we moved on to shaping the plastic in our saddle pentagon mold. However, due to oven limitations—at that time, we couldn’t use the huge pizza oven because we didn’t have the right cable (but we will next time)—we had to melt the plastic in multiple rounds. It took up to five separate batches to fill the entire mold, which resulted in:

- Difficulty pressing pieces together since the first batch had cooled by the time the second batch was ready. making it difficult to press properly.

- Uneven surface texture and incomplete molding.

Next step? Next time, we plan to use the pizza oven for larger-scale melting to ensure a more consistent and seamless process.

Improved Molding: Using the Pizza Oven

Switching to the pizza oven allowed us to melt the necessary amount of plastic in a single step. To make transferring onto the mold easier, we first placed the molten plastic on aluminum foil. While this method made handling easier, it also presented some challenges. The plastic is sometimes stuck to the foil, making it difficult to remove, and after one or two uses, the foil was broken, creating unnecessary waste.

Additionally, ensuring the plastic was evenly distributed was essential to properly filling the corners of the mold. In some cases, we had to add extra plastic during the melting process in the oven to achieve a complete shape.

Refining the Process: Silicone Mats & Framed Molds

Using a silicone mat improved the transfer process, as it prevented sticking and could be reused multiple times. However, some challenges remained:

- The mat’s slight thickness led to small waves or folds in the plastic panels.

- Excess material squeezed out of the mold needed to be trimmed before hardening.

To improve edge quality, we introduced a frame around the mold:

- The frame, secured with tension straps for easy removal after pressing, produced cleaner and more defined edges.

- However, due to the frame, we had to cut the silicone mat to fit the mold’s shape. This made it challenging to insert the mat, as there was little space to grip it. As a result, some edges had less material, and overall, there was sometimes too less material.

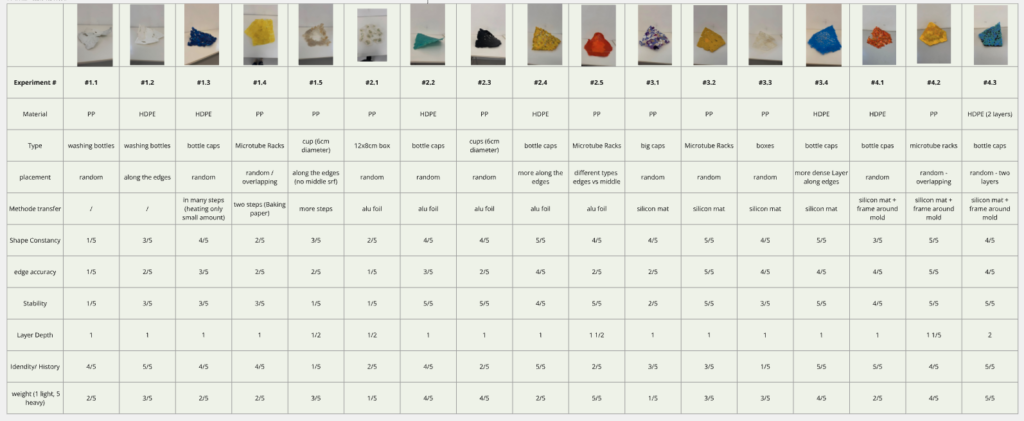

Evaluating the Plastic Panels

To systematically assess our molded panels, we categorized them based on:

- Structural Stability – Does the final panel hold together well, with strong bonding between the individual plastic pieces?

- Shape Consistency – How closely does it match the mold, and does it retain its intended form after cooling?

- Weight – How heavy is the panel?

- Artifact Visibility – Can the original plastic waste still be recognized, preserving its history?

We 3D-scanned each panel and found that many had slight deformations. One reason? Removing panels from the mold too early, while the plastic was still warm, led to shrinkage and warping.

Additionally, we observed that the artifact quality was fading—the small, recognizable plastic pieces we originally used to press the panels were blending into a more uniform, smooth surface. While this improved structural consistency, it also erased the original material’s identity, making it harder to see the history of the plastic waste we repurposed.

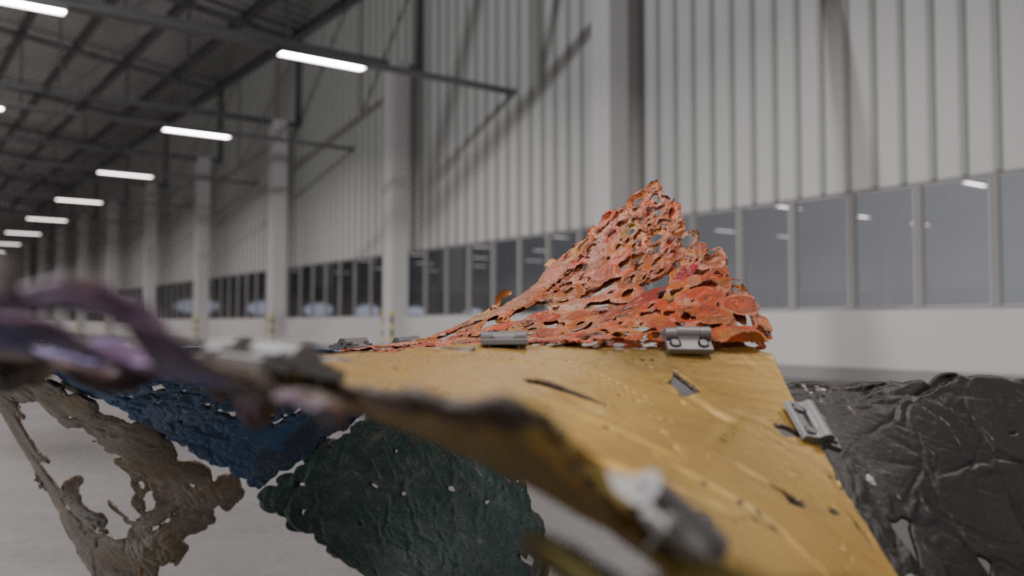

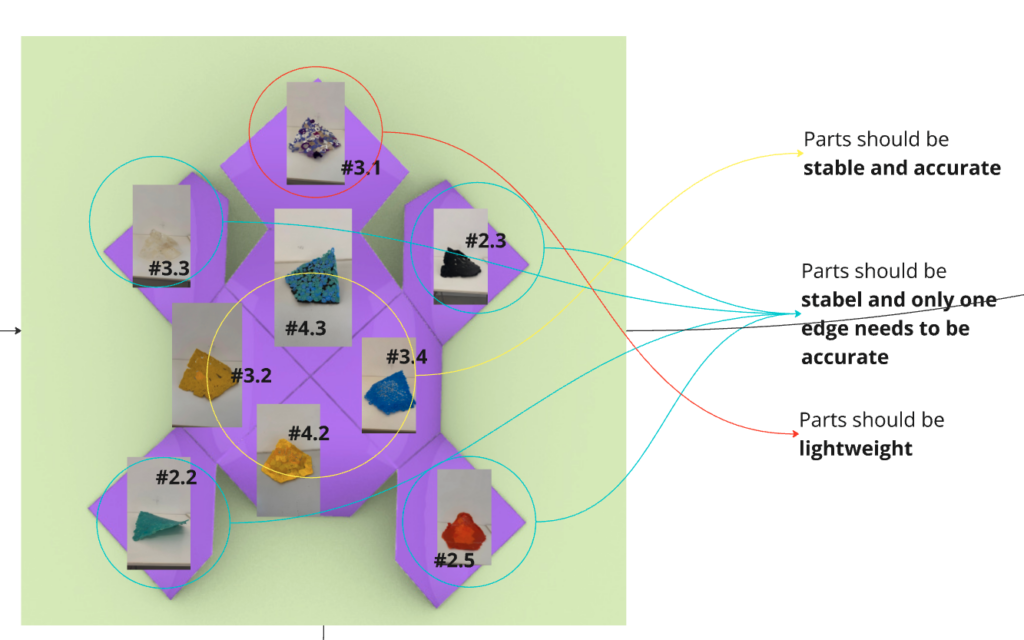

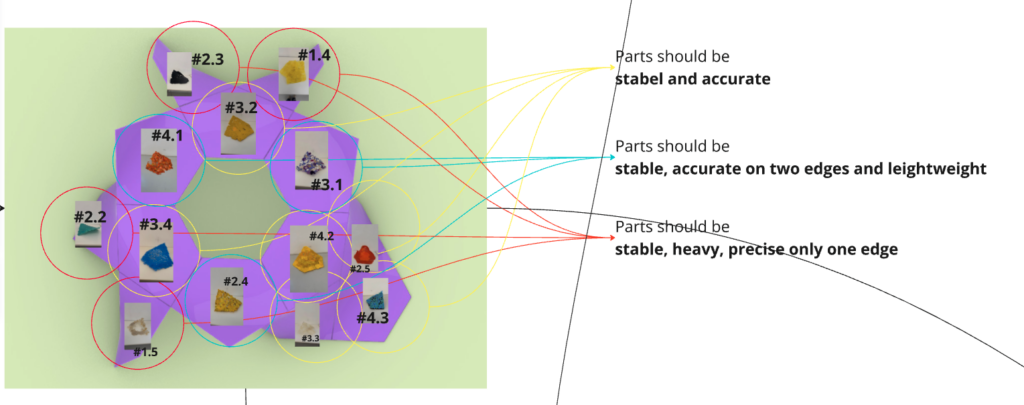

Structural Integration: Can These Panels Form a Structure?

To test real-world applications, we attempted to assemble the panels into two configurations:

- A 9-panel structure

2. A 13-panel structure

Factors affecting panel placement included:

- Structural stability

- Edge alignment accuracy

- Weight distribution

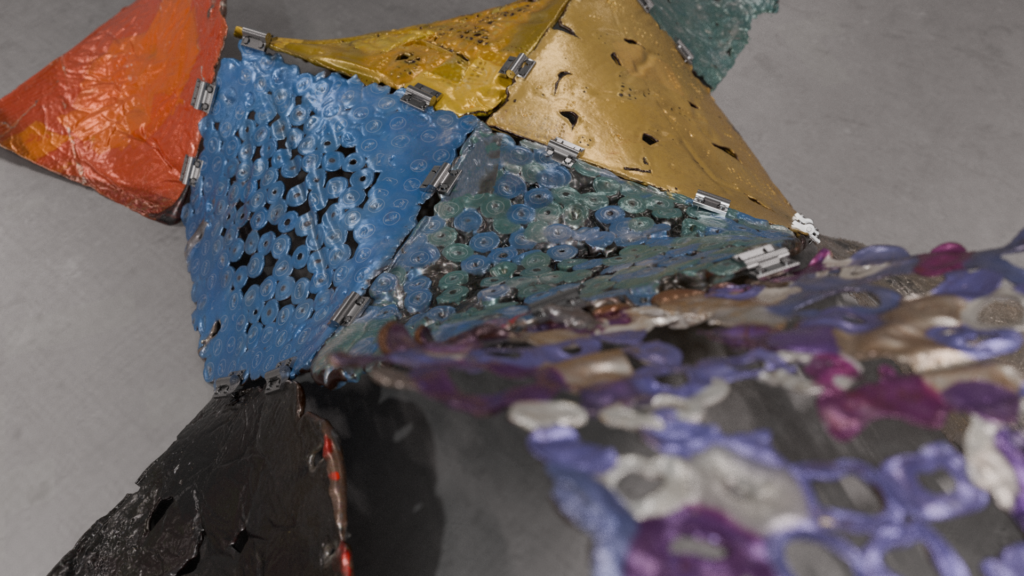

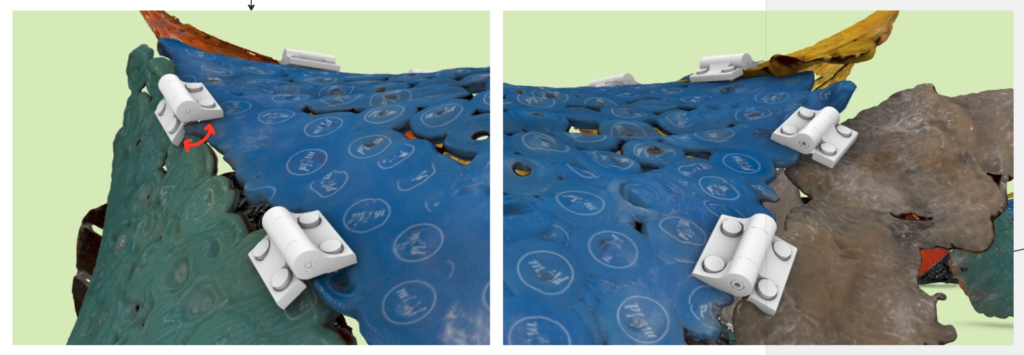

We also faced challenges in joining panels together. Due to variations in thickness and shape, a rigid connection system was impractical. Instead, we explored using adjustable friction hinges: Can be attached with screws, regardless of panel thickness. Allows for flexible joining angles to accommodate inaccuracies.

Final Thoughts

To better visualize the potential of these plastic panels, we created digital visualizations of these two different structural aggregations using hinges. However, upon reviewing the designs, we noticed that the original artifact quality had been lost. The pressed plastic had melted into a more uniform sheet, making it resemble a manufactured material rather than a collection of repurposed waste.

Additionally, the accuracy required for a precise joining system, such as the curved space system by Peter Pearce, proved challenging given the way we press the plastic, particularly in areas where thickness variations affected connectivity. Instead of aiming for continuous, seamless surfaces, we might explore alternative systems.