Learning from the WOBO bottle – (you can read more in our previous blog post) – we were fascinated by how the design embedded reuse directly into the form of the packaging.

We’ve been exploring the idea of giving packaging not just a second life through recycling, but a second function through design. This led us to experiment with how detergent bottles could be transformed into interlocking, modular components, inspired by Japanese joinery, 3D puzzle logic.

We drew inspiration from a variety of sources:

- The Tsugite Cube Master Pack, exploring Japanese wood joinery

- Traditional 3D interlocking puzzles, like the 6-piece burr

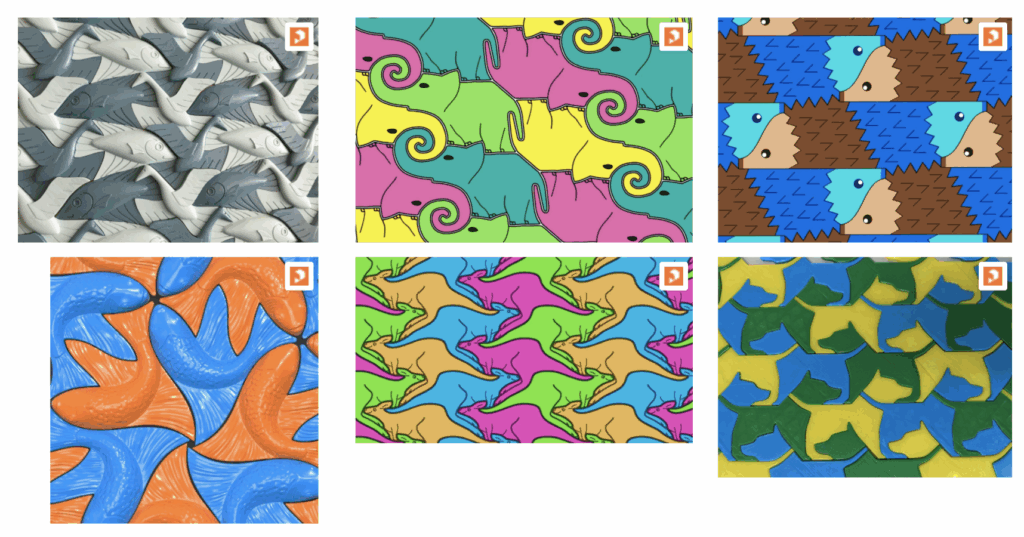

- Tessellating patterns and tiling concepts

- The scientific work Unlocking Interlocking Riddles (IST Austria), which investigates how complex shapes can fit and lock together

What unites these references is a shared idea: single units can combine into complex structures. They also encourage us to rethink the relationship between part and whole. And how design at the smallest scale can enable larger systems to emerge.

We began testing how a standard detergent bottle might be transformed into a modular building unit, without losing its original identity. The design had to meet two goals:

- Still function as a detergent bottle – with enough volume, a usable handle, ability to stand upright.

- Offer smart interlocking features – to stack, lock, and build something new after its primary use.

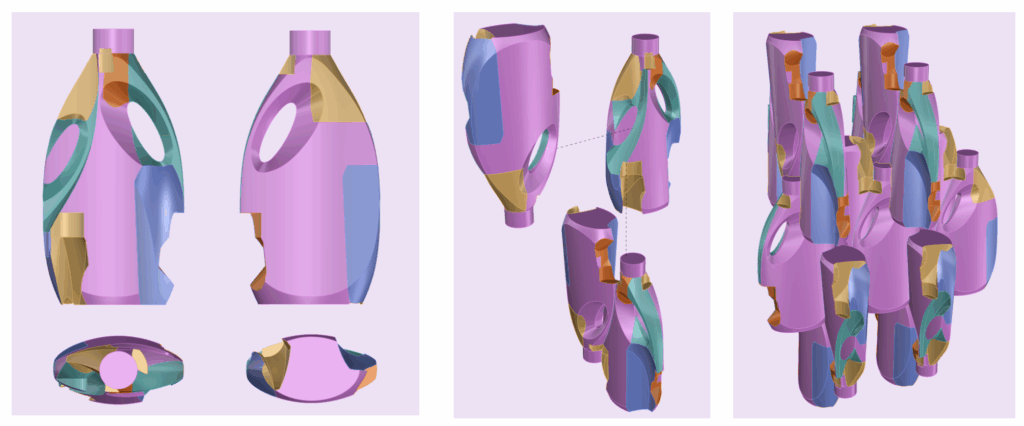

We focused on three key areas of the bottle as starting points for modification:

- The neck

- The handle

- The bottom

Early Prototypes and Experiments

Here are some of the first strategies we tested:

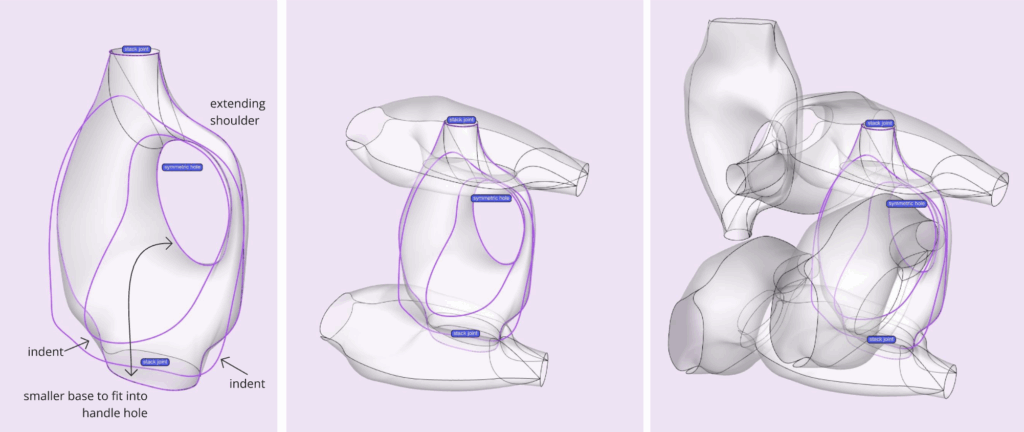

Modified Handle for Intersection

Creating a bigger handle where another bottle could fit with its neck or bottom.

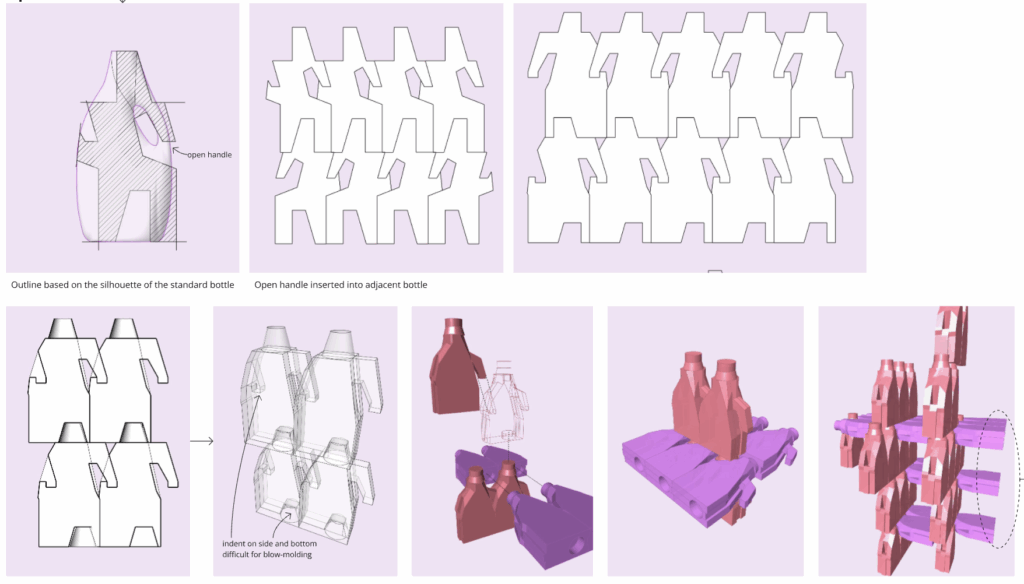

Open Handle Design

Removing part of the handle to allow tighter stacking and extending the neck to enable vertical-horizontal crossings in bottle walls.

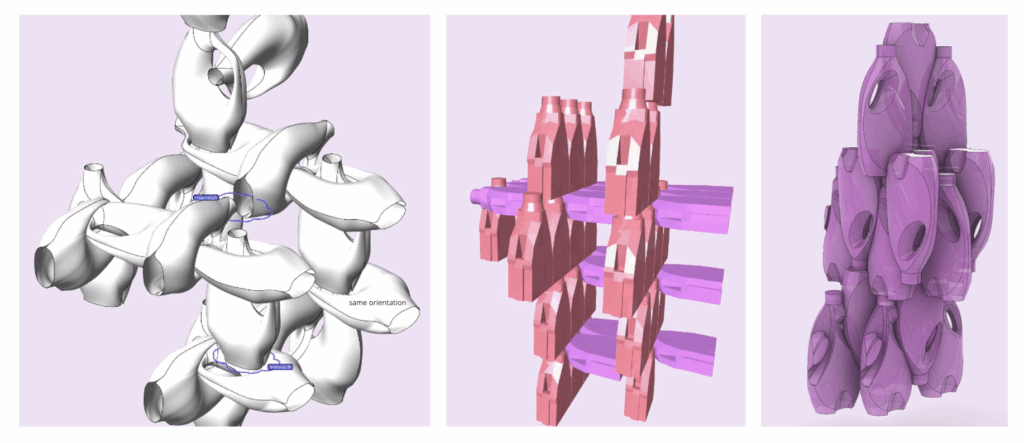

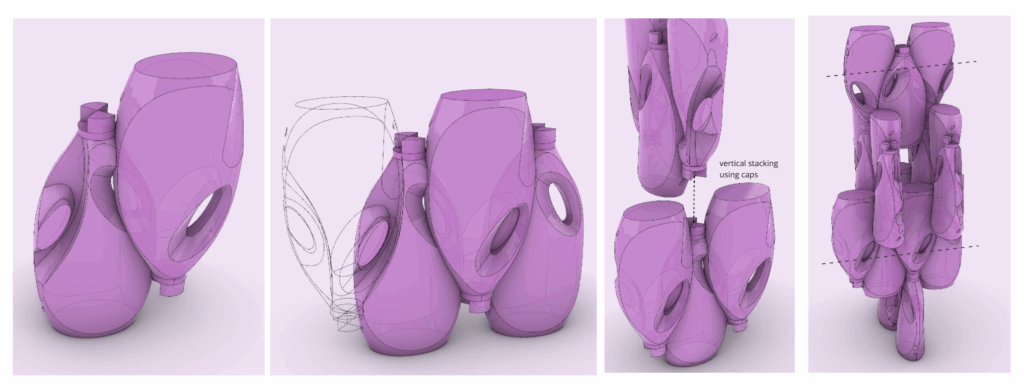

Boolean Imprint & Shape Echoing

Keeping a curved bottle shape but “printing” part of one bottle’s shape into another. The handles serve for horizontal locking; caps for vertical stacking.

Expanded Interlocking Zones

Increasing the number of connection points and intersections to enable more flexible assemblies.

After these experimentations, some questions started to emerge:

- Are we overcomplicating the design?

Does it become too difficult to use or understand? Can the average person assemble something with these bottles intuitively? - Does it still feel like a detergent bottle?

We risk losing the recognizability and potentially its usability, if we push the modifications too far. - Is there a structural limitation?

Many of the bottle assemblies naturally led to simple walls or floors. This raised concerns about the architectural potential of the system. - Production feasibility?

Some of the more intricate designs would likely be hard to produce or too costly with current manufacturing methods.

These concerns put the project on pause. But the question remains:

Can everyday packaging be designed not to be waste right afterwards, but to build structures?

The goal is not just to make recyclable packaging, but to extend the lifetime of a product by giving it a second purpose, designed into its shape from the very beginning.