In this part of our ongoing exploration into how detergent bottles can become building blocks, we return to the idea of designing the shape of the bottle. Not by changing the form in complex ways, but by applying what we’ve learned from space-filling geometry.

Instead of completely transforming the bottle, we focused on minimal modifications, while making it suitable for a second life as a modular element.

Revisiting Space-Filling Grids

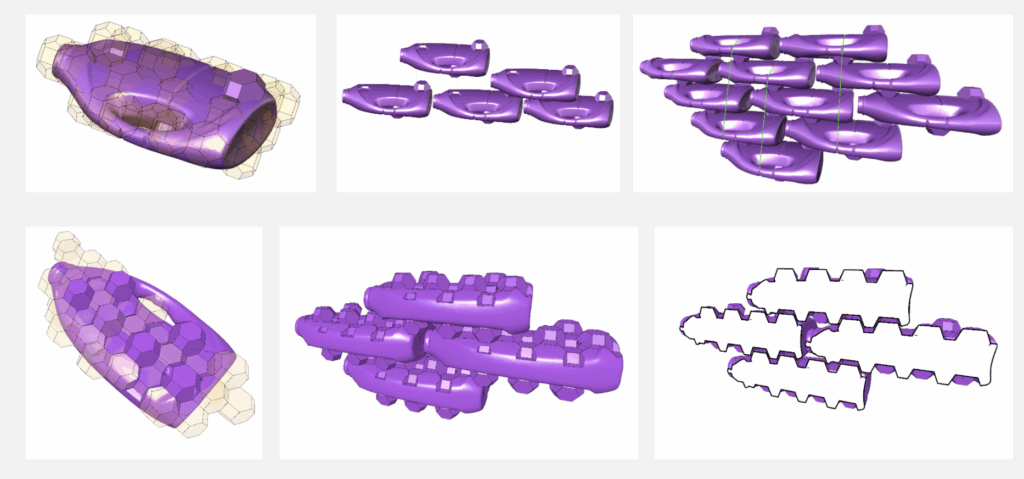

In a previous post, we explored how space-filling solids (like the truncated octahedron) could approximate the shape of a detergent bottle. We tried mapping detergent bottles into these grids or developing add-on components to match the geometry.

But what if, instead of adding parts or forcing bottles into a system, we subtracted the geometry from the bottle itself?

This approach allows the bottle to become part of the space-filling grid while remaining functionally unchanged but with a surface structure that enables bottles to interlock after use.

Our first attempt was to subtract and add solids, almost like turning the bottle into a Lego-like unit that could stack directly. We used the truncated octahedron, but quickly realized the form was too dominant. The bottle lost its character and became too bulky and unfamiliar.

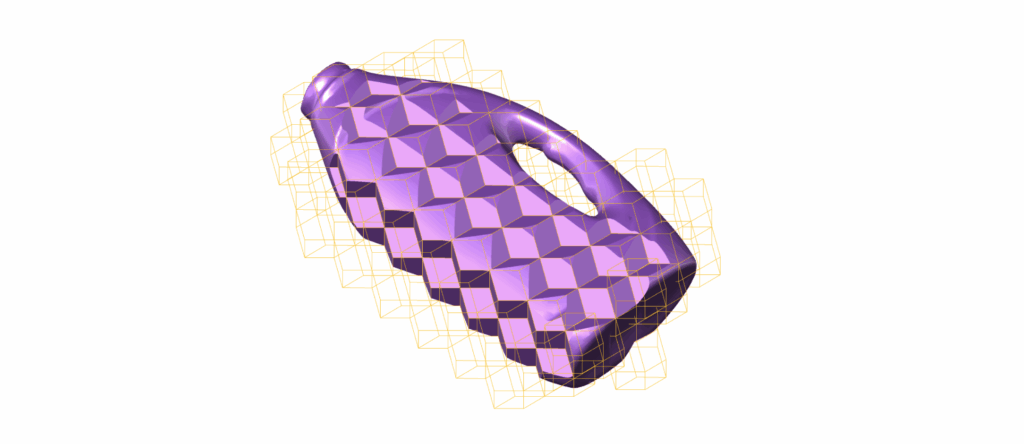

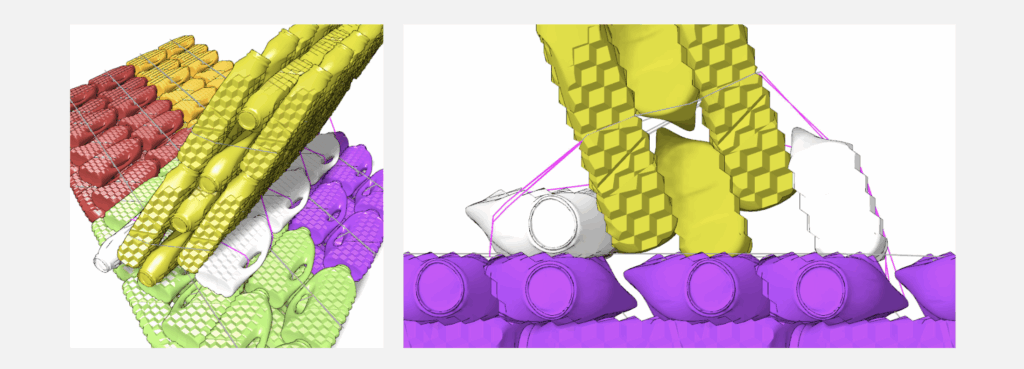

So we scaled back. Instead of reshaping the entire bottle, we focused on its two flat faces—typically the front and back. By intersecting these surfaces with a smaller-scale pattern based on the rhombic dodecahedron, we created a 3D pattern that acts as an interlocking surface.

Unlike traditional 90° designs, this pattern is based on 120° angles, allowing for criss-crossing layers.

Advantages:

- The handle, neck, and bottom remain untouched—so the bottle still functions and looks like a regular detergent bottle.

- The pattern can wrap around the sides, creating a continuous visual and structural language.

Once the surface pattern was applied, the bottles could be aligned and stacked—but how to keep them connected?

We saw potential in the handles as anchor points. By threading string or straps through them, multiple bottles can be tied together into panels.

This led to our first simple assembly system:

- Align bottles using the surface pattern.

- Thread string through the handles to connect the bottles.

- Tighten to form a solid surface panel.

These panels can then be combined into larger assemblies. But once we started exploring 3D constructions, new challenges appeared.

Once we tried stacking panels—especially combining flat ones with upright ones—we hit structural issues. Vertical panels weren’t stable enough on their own. We needed extra bottles to keep them upright, and the process became too complex and not intuitive for users. So we simplified again.

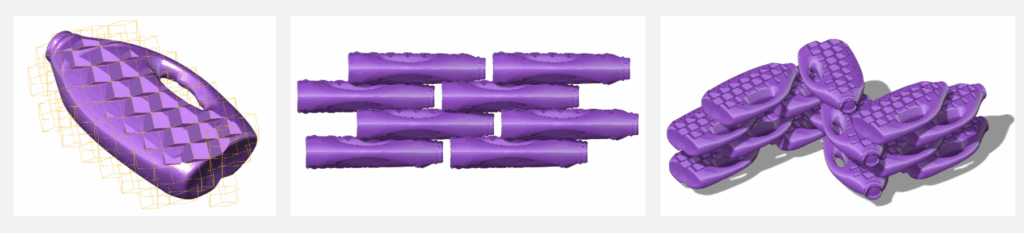

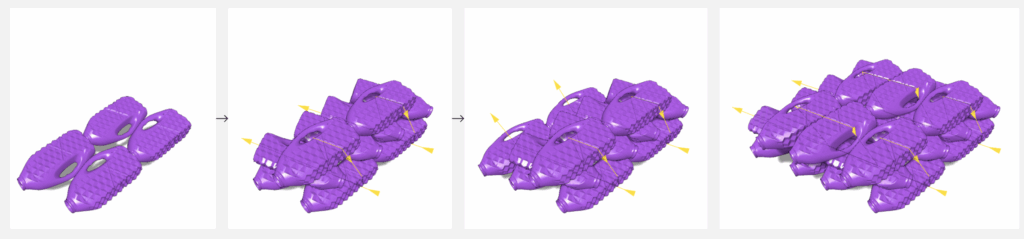

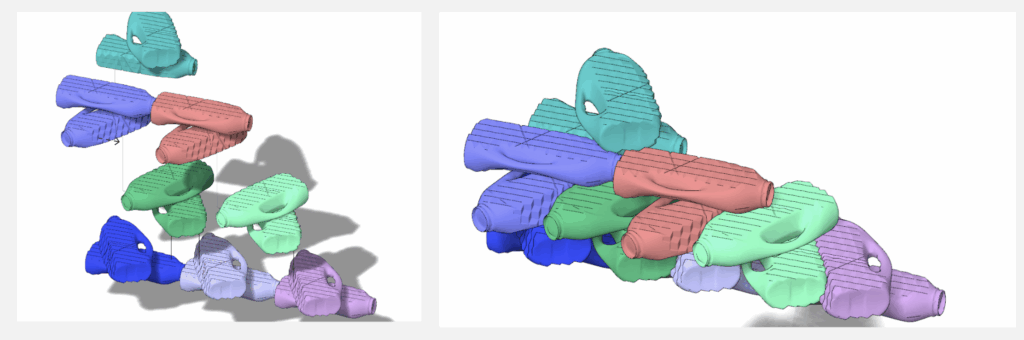

What if a “panel” was made of just two bottles?

By connecting two bottles at a 120° angle, we created a simple cross-shaped module that could serve as a new, easy-to-handle base unit. When these mini-panels are connected, the system begins to self-locking therefore not requires extra fasteners or materials.

This new system offers:

- Less complexity

- Fewer components

- More freedom: enabling curves, vaults, and even cantilevered forms

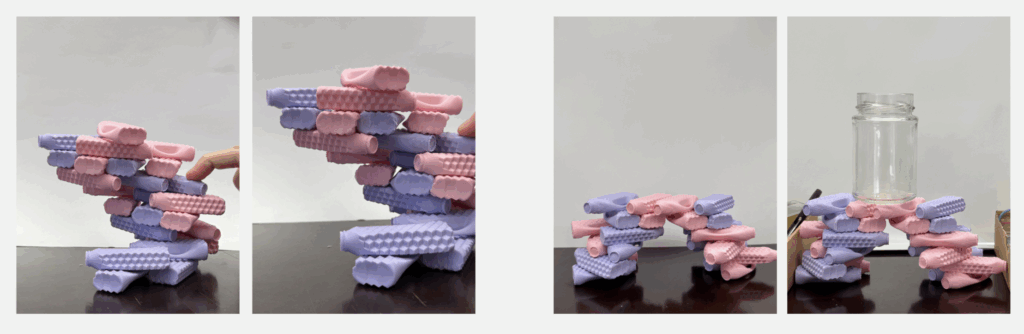

To test the idea quickly, we built a scaled-down prototype/ toy. Even at a smaller size, the interlocking logic worked.

We also made thoughts about weight distribution: by filling the bottom bottles with more water and leaving the top ones lighter, the structure would gain more stability without additional supports.

The intervention on our bottle still recalls the idea behind the Heineken WOBO, where the surface was also structured and the shape modified to allow stacking. However, in contrast to that concept, our cross-linked modules enable interlocking, resulting in more stable aggregations, without the need for mortar or additional fixations. This system allows for more diverse spatial configurations, including cantilevers, vaults.