Mid of August, we had the chance to visit Mack. The company is located in Altenmarkt, Austria, just a 30-minute drive from Vienna. Mack specializes in the production of technical plastic components using injection molding and extrusion blow molding, supported by their own in-house mold making.

We were warmly welcomed by Stefanie and Patrick, who dedicated the entire afternoon to showing us around. A big thank you for the time, effort, and the insights!

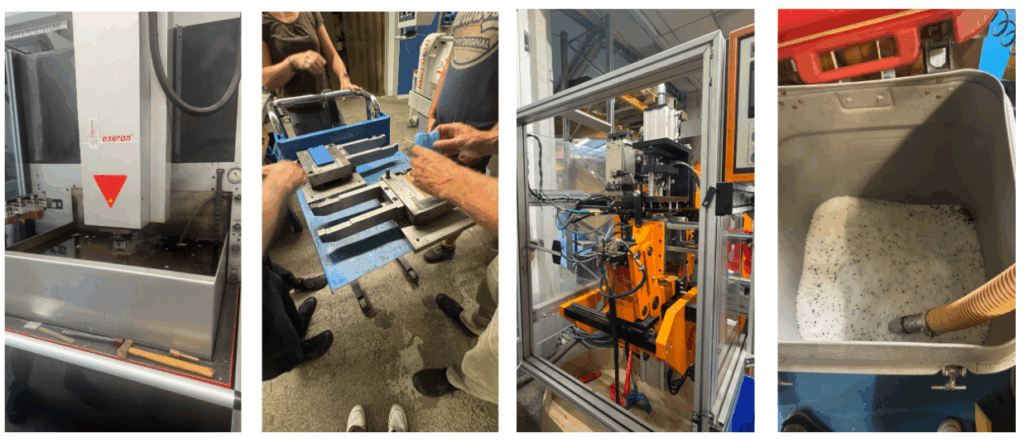

Mold Production and EDM Process

Our tour began in the mold production department. Mack creates its own steel molds, which are essential for plastic manufacturing. These molds are the most expensive and technically complex part of the process, as they must integrate all ventilation systems and technical details with extreme precision.

Molds and tools are produced using the Electrical Discharge Machining (EDM) process. In EDM, material is removed from steel by means of controlled electrical sparks within a dielectric fluid. This method enables extremely precise shaping and the creation of various surface textures, which directly affect the finish and quality of the final plastic product.

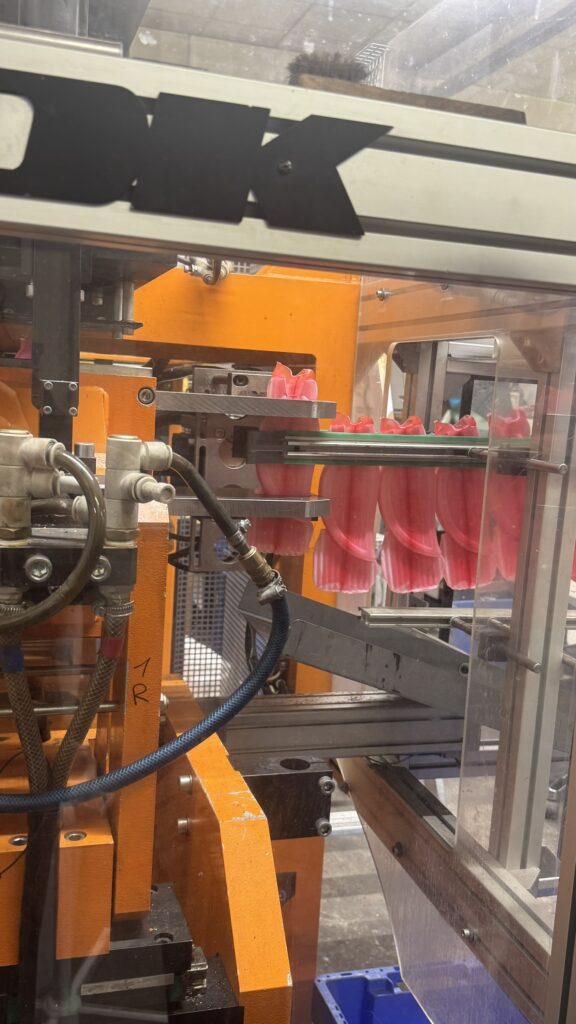

Extrusion Blow Molding in Action

Next, we got to watch extrusion blow molding live on a working machine. This was a highlight, as we had read and talked about the process before, but seeing it in real life was something else! Here’s the simplified process we observed:

- Plastic melts – Pellets are heated until soft.

- Tube is formed – The melted plastic is pushed out into a hollow tube

- Mold closes – A two-part mold closes around the tube.

- Air is blown in – The plastic is inflated like a balloon to fill the mold.

- Product is released – The mold opens, and the hollow plastic item comes out.

At Mack, their machine can produce bottles with a maximum capacity of 1.5 liters.

Injection Molding Machines

We then moved on to see several injection molding machines of different sizes and pressures. Here’s the basic process they follow:

- Plastic melts – Pellets are melted in a heated container.

- Plastic is injected – The molten plastic is pushed into a closed mold.

- Plastic fills the mold – The material flows through carefully designed channels inside the mold.

- Mold opens – Once the plastic has cooled and solidified.

- Part is ejected – Ejector pins push the finished part out of the mold.

We also had a look at the raw materials used. The base material is usually whitish, and only a small amount of colored pellets is added to achieve the desired color. For example, just a tiny amount of black pigment was enough to turn an entire batch into deep black plastic.

Our visit to Mack was both insightful and inspiring. From mold making with EDM, to watching extrusion blow molding and injection molding in action, we gained a much deeper understanding of plastic production.

Thank you to Stefanie and Patrick for their hospitality, explanations, and the time.