Besides varying capabilities for adapting to form variation of constituent parts, the surface-based bike-frame aggregations we studied previously, also have different bending flexibility.

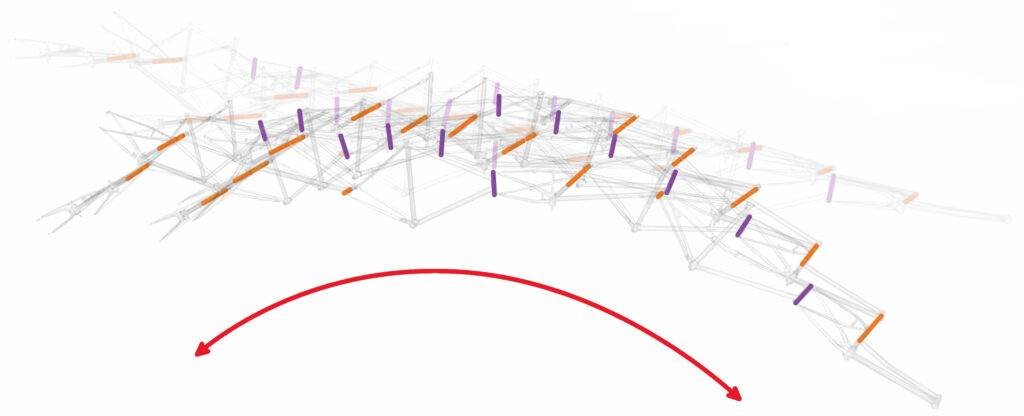

The main reason for the kinetic adaptability of these assemblies is the use of rotational axes as connections between frames. We had the idea, that besides the implementation of varying geometries, this adaptability could perhaps also be used to bend the entire bike-meshes into different forms and with that introduce another level of design control that operates from a top-down direction.

This study was also published in our paper that we presented at the ICSA 2025 conference in Antwerpen earlier this year.

Manually pulling and pushing the aggregation while the Kangaroo simulation for simultaneously co-aligning all connection axes is running, demonstrates how well patterns can deform. After some modifications, the aggregations are left untouched and the simulation continues freely until an equilibrium is found (no more improvements in connection-alignment are possible).

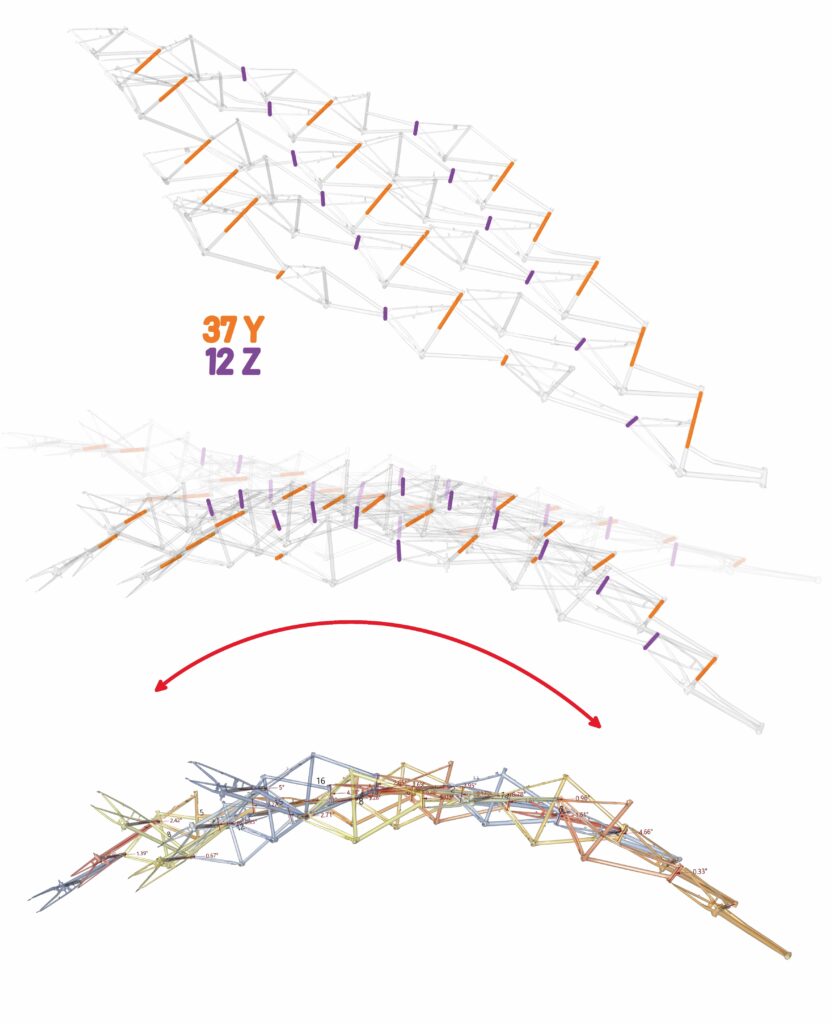

The study of pattern 1 shows, that after some rebound motions, the aggregation mostly remains in its bent state while alignment continues. This means there is relatively little resistance to global deformation, this has also been studied in one of our earlier studies with bike-frame lattices.

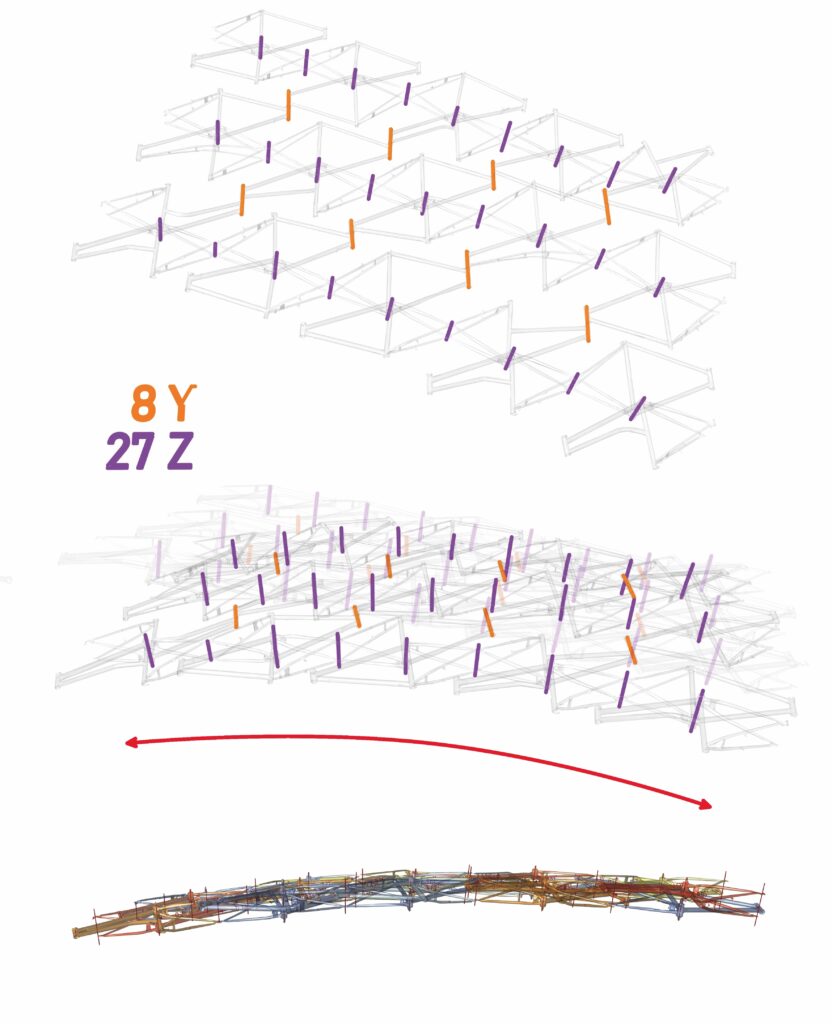

An aggregation based on pattern 2 has a much higher stiffness, the lattice almost entirely bends back to it’s planar configuration when the external force is removed.

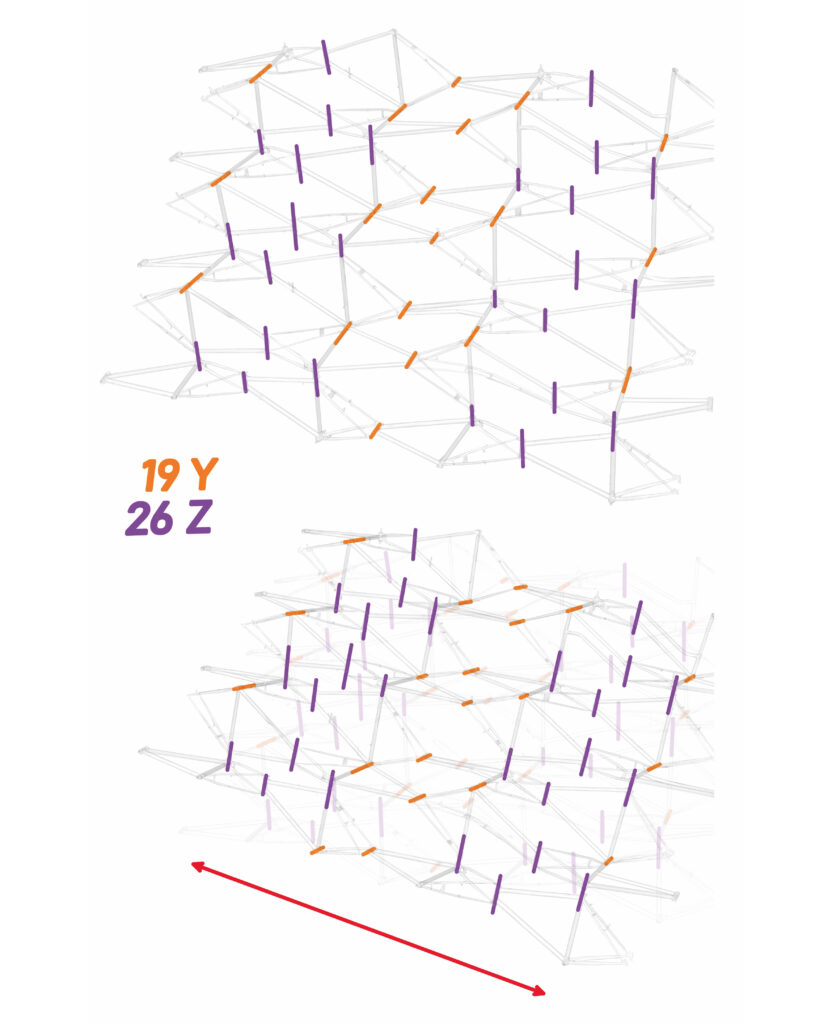

Pattern 3 has the most resistance to bending, it remains stable in flat state.

We realized, that the main factor for the varying degrees of bending flexibility is the ratio of connection axes orientations in X- and Y-direction, additionally the size of cells (number of parts needed to form a closed loop) in the lattice plays a role.