A new type of pattern for aggregating bicycle frames allows for more adaptability.

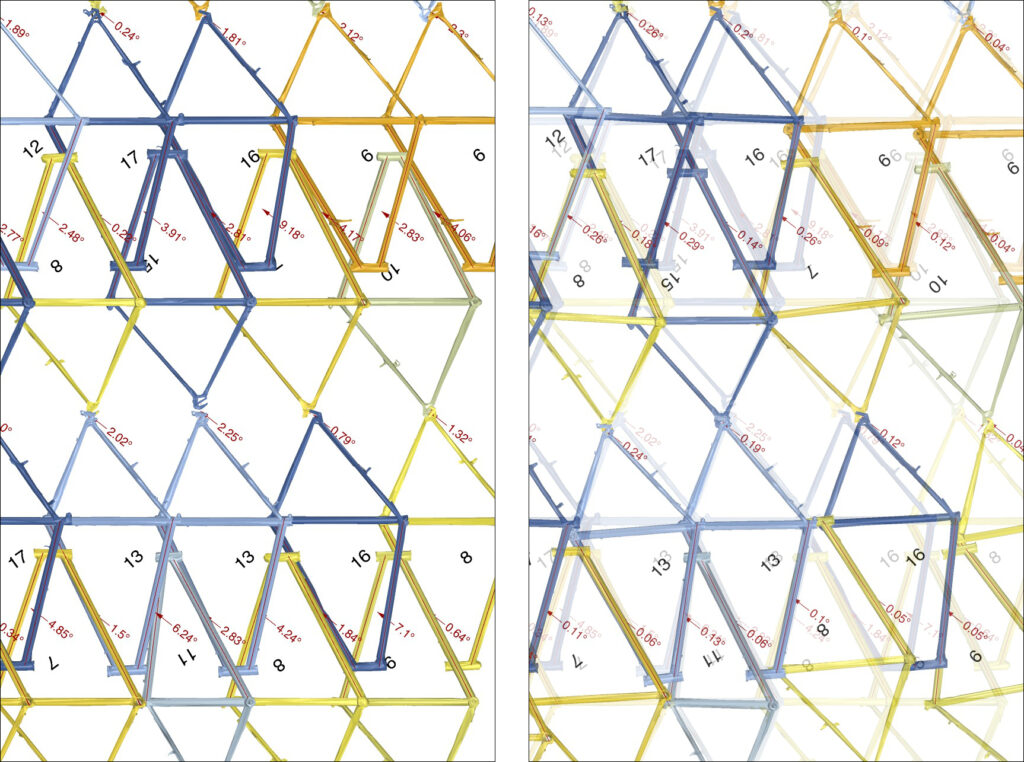

Previous studies have shown, that when using the standard joints that exist in a bicycle for part connections in an aggregated structure dis-alignment remains an issue. Despite efforts to find more optimal constellations of bike-frame parts by using k-means clustering and other approaches, deviations remain, that make it difficult to fabricate such a structure. We were able to build a physical sample, however, that was possible mainly because the sample was small, consisting of only 5 bicycles forming a closed loop. Because no further bike parts were connected at the periphery, the kinetic form-adaptation mechanism worked well to align all connections. Another issue was, that for such constructions custom fittings are needed for each connection type, and bike-frame specimen.

When instead using standard connectors that are normally used as pipe fixation collars (generously sponsored by Walraven) in combination with custom, but standardized spacers, it is possible to connect frames sideways, with adjacent tubes in parallel.

This results in a new pattern layout combining the new connection type with connections at the rear axle which also allows to use standard parts, in this case M10 threaded rods ( because different to other bicycle parts such as saddle or handlebars, wheel axes are standardized across models).

This system is capable of achieving much more precise alignment at connections, and because connection axes are oriented in parallel, the entire mesh of bike-frames could be deformed by maintaining alignment. This way, for example grid-shell structures could be designed.

In the physics simulation, first all connections are aligned in a flat state of the global structure, then a vertical force is applied to each frame, while parts on the edge of the mesh are fixed to the ground. This bends the bike-mesh to form a reverse catenary vault. Then, those vertical forces are removed and a connection alignment equilibrium is found that is almost identical to the flat state.

Despite the great adaptability as a geometric system, the structural model of a dome is not ideal because loads would be translated via friction at the joints. Physical stress tests with the pipe connectors have shown that even with maximum compression, the hinge mechanism cannot be locked to prevent buckling in a compression-loaded vault scenario as suggested above.

Other than The system’s capacity to adapt to part variation and also allow formability (eg. to configure a vault) could be used to create bent or folded structures in different global forms and orientations.

Folded structure combining bicycle frames and forks in horizontal and vertical orientation.